Food contamination sources

Food provides an ideal nutrition source for microorganisms and generally has a

pH value in the range needed to contribute to proliferation. During harvesting, processing, distribution, and preparation, food is contaminated with soil, air, and waterborne microorganisms. These microorganisms and those from contamination through slaughtering can migrate to the skeletal muscles via the circulatory system. When carcasses and cuts are subsequently handled through the food distribution channels, where they are reduced to retail cuts, they are subjected to an increasing number of microorganisms from the cut surfaces. The infecting microorganism is ingested and then multiplies, as is true for Salmonella, Shigella, and some enteropathogenic Escherichia coli. Toxins are released as the microorganisms multiply, sporulate, or lyse. Examples of such infections are C. perfringens and some strains of enteropathogenic E. coli.

TRANSFER OF CONTAMINATION

Before a foodborne illness can occur, food-borne disease transmission requires that several conditions be met. The presence of only a few pathogens in a food will generally not cause an illness, although regulatory agencies still consider this a potentially hazardous situation.

Chain of Infection

A chain of infection is a series of related events or factors that must exist or material-ize and be linked together before an infection will occur. These links can be identified as agent, source, mode of transmission, and host. The essential links in the infectious process must be contained in such a chain. The causative factors that are necessary for the transmission of a bacterial food-borne disease are:Transmission of the causative agent from the environment in which the food

The chain of infection is produced, processed, or prepared to the food itself.

Conditions such as required nutrients, moisture, pH, oxidation–reduction potential, lack of competitive microorganisms, and lack of inhibitors must also exist for contaminants to survive and grow. Contaminated food must remain in a suitable temperature range for a sufficient time to permit growth to a level capable of causing infection or intoxication. The infection chain emphasizes a multiple causation of foodborne diseases. The presence of the disease agent is indispensable, but all of the steps are essential in the designated sequence before foodborne disease can result.

Web of Causation-The web of causation as modified is a complex flow chart that indicates the factors that affect the transmission of foodborne disease. This presentation of disease causation attempts to incorporate all of the factors and their complex interrelationships. These webs, generally oversimplified schematic representations of disease transmission processes, will not be illustrated because a very large and comprehensive figure would be required to include all pathogenic microorganisms affecting all foods.

CONTAMINATION OF FOODS

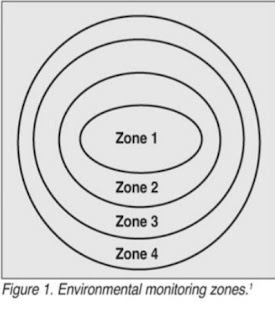

A viable way for the identification of contamination sources in food establishments is to incorporate the “zonal” approach to environmental monitoring.

This technique is an effective way to identify potential trouble spots and maintain effective sanitation control strategies through targeting

appropriate areas of concern. The zonal approach is designed as a bull’s eye target with

the center circle or Zone 1 representing the most critical areas for cleaning and

sanitizing—primarily direct food-contact surfaces. These areas include, but are not

limited to, production equipment, utensils, and containers with direct contact with

foods. The second circle (Zone 2) of the bull’s eye target includes the areas of concern

for cleaning and sanitizing of indirect food-contact surfaces such as equipment parts or

other surfaces that personnel may come in contact with near Zone 1. Examples of

indirect contact surfaces include portions of the plant environment such as drains,

utility pipes, heating ventilation, and air conditioning system equipment, etc. Zone 3

includes floors, walls, and other items in contact with floors, walls, cleaning equipment,

and other items in the processing area that are not as close to foods as in Zone 2. Zone

4 includes maintenance equipment and areas further away from production such as

hallways, entrances, and welfare facilities. One of the most viable contamination sources is the food product itself. Waste products that are not handled in a sanitary way

become contaminated and support microbial growth. ATP bioluminescence and protein

tests are non-microbial tests that detect soil and debris that cannot be seen by the naked

eye. ATP bioluminescence detects any cells that contain ATP; whereas, protein tests

identify protein in soils, which is an indicator of contamination such as feces.

Dairy Products

Potential contamination of food by humans production and to eliminate disease

problems in dairy cows has contributed to more wholesome dairy products, although

contamination can occur from the udders of cows and milking equipment. The subsequent pasteurization in processing plants has further reduced milkborne disease microorganisms. Nevertheless, dairy products are vulnerable to cross-contamination from items that have not been pasteurized. Because not all dairy products are pasteurized, the presence of pathogens(especially Listeria monocytogenes) in this industry has increased.

Red Meat Products- The muscle tissues of healthy living animals are nearly free of

microorganisms. Contamination of meat occurs from the external surface, such as hair,

skin, and the gastrointestinal and respiratory tracts. The animal’s white blood cells and

the antibodies developed throughout their lives effectively control infectious agents in

the living body. These internal defense mechanisms are destroyed when blood is

removed during harvesting.Initial microbial inoculation of meat results from the introduction of microorganisms into the vascular system when contaminated knives are used for exsanguination. The vascular system rapidly disseminates these microorganisms throughout the body.

Contamination subsequently occurs by the introduction of microorganisms on the meat

surfaces in operations per-formed during slaughtering, cutting, processing, storage, and

distribution of meat. Other contamination can occur by contact of the carcass with the

hide, feet, manure, dirt, and visceral contents from punctured digestive organisms.

Poultry Products- Poultry is vulnerable to contamination especially Salmonella and

Campylobacter organ-isms during processing. The processing of poultry, especially defeathering and evisceration, permits an opportunity for the distribution of microorganisms among carcasses. Contaminated hands and gloves and other tools of processing plant workers also con-tribute to the transmission of salmonellae.

Seafood Products- Seafoods are excellent substrates for microbial growth and are

vulnerable to contamination during harvesting, processing, distribution, and marketing.

They are excel-lent sources of proteins and amino acids, B vitamins, and a number of

minerals required in bacterial nutrition. Seafoods are handled extensively from

harvesting to consumption. Because they are frequently stored for long periods of time

without prior refrigeration, contamination and growth of spoilage microorganisms and

microbes of public health concern can occur.

Adjuncts: Ingredients (especially spices) are potential vehicles of harmful or potentially harmful microorganisms and toxins. The amounts and types of these agents

vary with place and method of harvesting, type of food ingredient, processing technique, and handling. The food plant management team should be aware of the

hazards connected with individual incoming ingredients. Only supplies and materials

gathered in accordance with recognized good practices should be used. This

requirement also applies to control of testing of critical materials, either by the

manufacturing firm, receiving establishment, or both.

OTHER CONTAMINATION SOURCES

Equipment- Contamination of equipment occurs during production, as well as when

the equipment is idle. Even with hygienic design features, equipment can collect

microorganisms and other debris from the air, as well as from employees and materials.

Product contamination of equipment is reduced through improved hygienic design and

more effective cleaning.

EmployeesOf all the viable means of exposing microorganisms to food, employees are the

largest contamination source. Employees who do not follow sanitary practices

contaminate food that they touch, with spoilage and pathogenic microorganisms that

they come in contact with through work and other parts of the environment. The hands,

hair, nose, and mouth harbor microorganisms that can be transferred to the food during

processing, packaging, preparation, and service by touching, breathing, coughing, or

sneezing. Because the human body is warm, microorganisms proliferate rapidly,

especially in the absence of hygienic practices.

After the chain of infection is broken the spreading of bacteria from one location to

another can be prevented. Generally, the mishandling of food by people perpetuates the

chain of infection until someone becomes ill or dies before corrective actions are taken

to prevent additional outbreaks. If every person that handles food could achieve

appropriate personal hygiene, food contamination could be minimized. Every

employee involved with food manufacturing can play a very important role in

preventing food contamination.

Air and Water- Water serves as a cleaning medium during the cleaning operation and

is an ingredient added in the formulation of various processed foods. It can also serve

as a source of contamination. If excessive contamination exists, another water source

should be obtained, or the existing source should be treated with chemicals (such as

ultraviolet units) or other methods.

Contamination can result from airborne microorganisms in food processing,

packaging, storage, and preparation areas. This contamination can result from unclean

air surrounding the food plant or from contamination through improper sanitary

practices. The most effective methods of reducing air contamination are through

sanitary practices, filtering of air entering the food pro-cessing and preparation areas,

and protection from air by appropriate packaging techniques and materials.

Sewage- Raw, untreated sewage can contain pathogens that have been eliminated from

the human body, as well as other materials of the environment. Examples are microorganisms causing typhoid and paratyphoid fevers, dysentery, and infectious

hepatitis. Sewage may contaminate food and equipment through faulty plumbing.

If raw sewage drains or flows into potable water lines, wells, rivers, lakes, and ocean

bays, the water and living organisms such as seafood are contaminated. To prevent this

contamination, privies and septic tanks should be sufficiently separated from wells,

streams, and other bodies of water. Raw sewage should not be applied to fields where

fruits and vegetables are grown. Insects and Rodents- Flies and cockroaches are associated with living quarters, eating establishments, and food processing facilities, as well as with toi-lets, garbage, and other filth. These pests transfer filth from contaminated areas to food through their waste products; mouth, feet, and other body parts; while the regurgitation of filth onto clean food during consumption. To stop contamination from these pests, eradication is

necessary, and food processing, preparation, and serving areas should be protected

against their entry.

PROTECTION AGAINST CONTAMINATION

The Environment- Foods should not be touched by human hands when consumed

uncooked or after cooking, if such contact can be avoided. If contact is necessary,

workers should thoroughly wash their hands prior to and periodically during the time

that contact is necessary. Contact with hands can be reduced by the use of disposable

plastic gloves during food processing, preparation, and service. A processed or

prepared food, either in storage or ready for serving or holding, should be covered with

a close-fitting clean cover that will not collect loose dust, lint, or other debris. If the

nature of the food does not permit this method of protection, it should be placed in an

enclosed, dust-free cabinet at the appropriate temperature. Any food that has touched

any unclean surface should be cleaned thoroughly or discarded. Equipment and utensils for food processing, packaging, preparation, and service should be cleaned and sanitized between uses. Foodservice employees should be instructed to handle dishes and eating utensils in such a way that their hands do not touch any surface that will be

in contact with food or the consumer’s mouth.

Storage- Storage facilities should provide adequate space with appropriate control and

protection against dust, insects, rodents, and other extraneous matter. Organized

storage lay-outs with appropriate stock rotation can frequently reduce contamination

and facilitate cleaning, and can contribute to a tidier operation. In addition, storage area

floors can be swept or scrubbed and shelves and/or racks cleaned with appropriate

cleaning com-pounds and subsequent sanitizing. Trash and garbage should not be

permitted to accumulate in a food storage area.

Litter and Garbage-The food industry generates a large volume of wastes: used

packaging materials, containers, and waste products. To reduce contamination, refuse

should be placed in appropriate containers for removal from the food area. The

preferred disposal method (required by some regulatory agencies) is to use containers

for garbage that are separated from those for disposal of litter and rubbish. Clean,

disinfected receptacles should be located in work areas to accommodate waste food

particles and packaging materials. These receptacles should be seamless, with close-

fitting lids that should be kept closed except when the receptacles are being filled and

emptied.

Toxic Substances- Poisons and toxic chemicals should not be stored near food

products. In fact, only chemicals required for cleaning should be stored on the same

premises. Cleaning com-pounds should be clearly labeled. Only cleaning compounds,

supplies, utensils, and equipment approved by regulatory or other agencies should be

used in food handling, processing, and preparation.

0 Comments

Send feedback